3 Things To Remember While Floor Marking in Factories

Floor marking is critical for many types of businesses, including warehouses, commercial spaces, offices, and many more. When it comes to factories and industrial plants, floor and safety line marking becomes the lifeblood for the business operations.

Proper factory line marking helps businesses to ensure everything in their factories runs smoothly. With minimal investment, businesses can ensure safety, improved business performance, and better management of their factories.

However, improper or inefficient line marking or the use of the wrong products can create confusion in the factory environment due to premature fading and wear, and lead to accidents, asset damages, and business loss. It can also make the workforce less motivated to work and lead to incompetent business services.

Do you have a factory and want to mark the floor for safety compliance and efficient business operations? Before choosing marking services, you should know some important factors to ensure effective line marking for your facility.

It can help you to choose the right line marking contractors in Melbourne who can provide you with effective floor marking strategy and proper marking solutions.

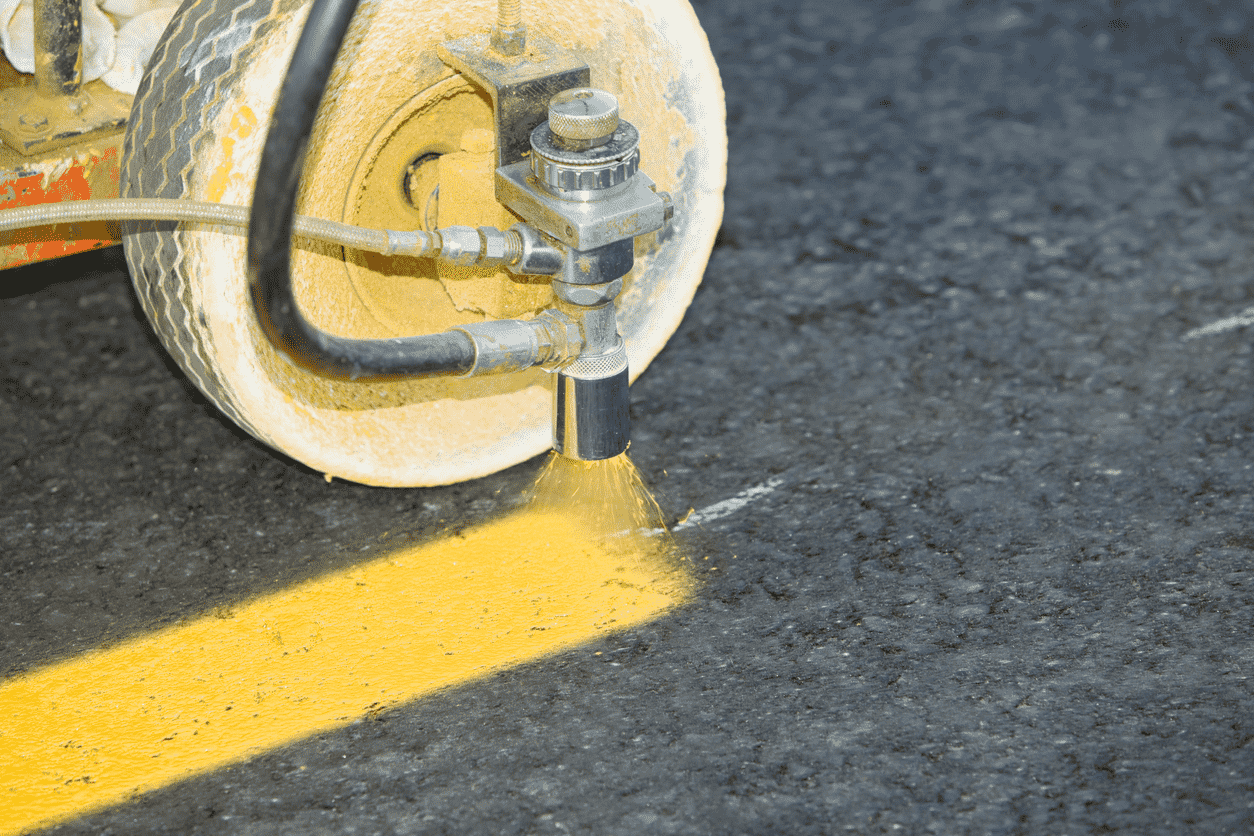

1. Choose The Right Floor Marking Material

There are many marking materials and coating options that are available for factories that can match their specific requirements. Note that you can use a mix of these marking options if you find that they can provide you with the best results.

Chlorinated Rubber Resin

Rubber chlorinated paint is a single pack, fast drying coating based on a durable alkyd modified chlorinated rubber resin. It can be applied to bitumen or concrete without causing bleeding or discolouration. It is renowned for its durability, high visibility, and fast drying in a short timeframe.

2-Pack Epoxy

2-pack epoxy is renowned for its durability and the minimal preparation that is required. However, a long application curing window is required, usually a minimum of 14 hours. Please note that epoxies can chalk over time if exposed to UV. A top coat of weatherable coating is desirable externally.

Polyaspartic Coatings

Polyaspartic coatings are durable coatings with benefits, including short curing times, high build thickeners, VOC free, high solids content, and UV stability. However, the downside is that preparation is more extensive, and the material is much more expensive.

Signs And Shapes

Floor marking signs and shapes can convey specific information efficiently. Shapes and signs can be fixed on the floor or wall using strong adhesives.

With efficient use of signs and shapes, you can ensure the proper movement of employees, machines, and products in the right direction as defined by you. For instance, by marking footprints on floors, you can guide and control the movement of your workforce inside the factory. Similarly, arrows can give direction to vehicles, and signs like stop signs, exit signs, and warning signs can help your workforce to take appropriate actions for safety.

2. Know The Important Floor Marking Standards

According to Safe Work Australia, people and vehicles should not interact with each other – to protect the workforce and pedestrians. It also instructs all industrial facilities to take measures to avoid the collision of vehicles and machines.

It means that your factory floor should be clearly marked and well maintained to ensure the safety of your workforce and critical assets.

Safe Work Australia also asks businesses to use signs and road markings to alert pedestrians and vehicle operators about traffic hazards in the workplace, especially in places where pedestrians should cross the route of vehicles and equipment.

It also instructs businesses to use signs to indicate parking areas, safety zones, and speed limits. You should also use signs for steep gradients, blind corners, and forklift routes.

Safe Work Australia also demands proper maintenance of floor markings so that pedestrians can easily see them.

While the regulatory body does not instruct particular colour codes for floor markings, it is important to follow uniform colours for line marking across your facility. It can avoid confusion and ensure the efficient and safe movement of people, vehicles, and equipment.

3. Learn The Advantages Of Floor Marking

Before choosing floor marking for your factory or industrial facility, it is also important for you to know its benefits. It can help you to educate your workforce to always follow the floor marking.

With clearly marked spaces for employees and machines, you can improve the safety of your employees and reduce workplace accidents. It increases the morale of your employees, and that can reflect in the performance of your business.

It can also improve the organisation of your facility and help you to manage it better. The floor markings help the workforce to identify where equipment should be stored, the boundary for work areas, storage areas for different products, and much more.

Conclusion

Before making your choice, call Mainliner for best practice advice. As one of the leading line marking companies in Melbourne, we can recommend the best coating material for specific areas at your factory or warehouse.